Document Management Systems for Engineering Projects: A Complete Guide

A document management system (DMS) is designed to organise, store, and control documentation throughout its lifecycle. For engineering projects, where custom-built equipment and complex designs generate vast amounts of technical documents, this is a necessity. In this guide, I’ll explore why engineering projects demand more than standard document control, the risks of poor management, and how Proarc EDMS delivers on these expectations.

Contents

- Why Do Engineering Projects Need a Document Management System?

- The Risks of Poor Document Control in Engineering

- What Should I Look for in a Document Management System?

- How Does a Document Management System Workflow Improve Engineering Projects?

- Summary

- Document Management Systems for Engineering FAQs

Why Do Engineering Projects Need a Document Management System?

Engineering projects are fundamentally different from standard construction work. Instead of cookie-cutter designs, you often require custom-built, one-of-a-kind equipment: think chemical treatment systems or wastewater management systems. These unique solutions generate vast quantities of technical documentation, such as drawings, materials lists, installation instructions, safe operation guidelines, maintenance procedures, etc.

Engineering projects are fundamentally different from standard construction work. Instead of cookie-cutter designs, you often require custom-built, one-of-a-kind equipment: think chemical treatment systems or wastewater management systems. These unique solutions generate vast quantities of technical documentation, such as drawings, materials lists, installation instructions, safe operation guidelines, maintenance procedures, etc.

You know firsthand how complex this documentation can become: each file often goes through multiple review cycles before it’s approved for construction or accepted as an accurate representation of the as-built asset. On top of that, you’re also juggling commercial documentation: contracts, purchase orders, reports, transmittals and constant streams of correspondence.

Managing all of this requires more than just a central repository of documents. What you actually need is a structured, integrated document control process that includes gatekeeping services to make sure incoming information is valid and categorised and ensure outgoing information is approved and complete.

The Risks of Poor Document Control in Engineering

In engineering projects, the consequences of not having a trusted document management system with integrated document control processes can be severe:

Rework

Working with incorrect or outdated documents or drawings can lead to incorrect installation and rework, ballooning costs and creating a cascading effect on the schedule’s critical path.

Compliance Failures and Safety Incidents

Unapproved or inaccurate documentation can compromise regulatory compliance, leading to schedule delays and potential penalties.

Safety Incidents

The wrong revision of a design document can create hazards on a job site that expose construction teams to injury risk or lead to faulty installations that result in injuries or damage down the road.

Inability to Defend Claims and Litigation

Without a reliable document control system, the history of revisions, approvals, and distribution becomes impossible to discern, affecting your ability to defend claims or litigation.

Uncontrolled Collaboration

Without controlled methods for sharing accurate document and drawing versions with external partners, inaccurate file copies delivered via email increase the risk of errors.

What Should I Look for in a Document Management System?

Selecting the right solution for engineering projects means finding a document control system that’s purpose-built for these types of projects and includes:

1. Support for Complex Documentation

Engineering projects generate complex documents that demand specialised document handling capabilities. Look for:

- Ability to manage engineering file types and interactions, including viewing, markup annotations, stamps & symbols, format conversion, multi-file documents and references between them

- Controlled change history with registered document revisions (not just file versions), including revision-level coding

- Document relations to represent design interfaces and interdependencies

- Bulk import and REST API tools to support a high volume of documents and data originating from design systems

- User experience tailored to engineering teams to easily find and update information, review and approve documents, collaborate with suppliers, and monitor deliverable status and progress for clients

Proarc is purpose-built for engineering environments, offering structured repositories and metadata-driven organisation for complex information. It ensures that every document is linked to the correct and complete set of technical references: equipment tags, systems, sub-systems, work breakdown codes and project phases. Changes are recorded in an official revision history. This gives engineers and project team members a central source of truth where information is easy to find and share with confidence.

2. Information Management Standards Compliance

From internal policies to client requirements, your document management system needs to flex to conform to multiple information management standards. Look for:

- Flexible document numbering to accommodate your organisation’s project standards while also mapping to supplier conventions and unique client requirements

- Audit history capturing event in the document lifecycle stamped with dates and performers

- Enforcement of document access controls to prevent unauthorised use

- Designation of authority and responsibility for information types or work processes

- Configurable classification and metadata codes to support multiple standards, so that all stakeholders can verify information is complete and correct in different contexts

- Ability to consume, import or export information in compliance with industry standards for supply chain integration

- Technology standards to streamline integration with other systems, such as REST APIs, cloud services, identity and authentication platforms, etc.

Proarc provides flexibility to configure multiple information standards and policies to help support compliance and identify deviations.

3. Searchability and Accessibility

Finding the right document quickly is critical in fast-moving projects. Poor search capabilities waste time and can create frustration. Look for:

- Configurable metadata search forms to make it easy to search engineering information types, project codes, equipment tags, etc.

- Advanced reusable search queries, so that teams can repeatedly produce real-time updated sets of documents according to work packages, clients, systems, date ranges, or other criteria

- Dynamic folders that automatically build navigation paths from project metadata, allowing engineers to browse documents through familiar categories like discipline, system, tag, or work package, for intuitive, guided access to the information you need

- Integration with Microsoft 365, including Office, Teams, and Outlook, so that users can work within familiar desktop and web applications

- AI-based tools with semantic features, including natural language processing, to uncover more relevant information

Proarc’s powerful search tools deliver precise results instantly and make it easy with project nomenclature and familiar user experiences.

4. Workflow Automation

Manual processes slow projects down and increase the chance of mistakes. Automation keeps teams aligned and projects on schedule. Look for:

- Pre-configured engineering workflows, including inter-disciplinary squad checks, supplier submittal reviews, and client issuance reviews

- Integrated view and markup tools so that engineers can apply annotations, symbols, stamps and signatures

- Role-based task assignments, group inboxes, authorisation matrix and distribution lists, to ensure authorised experts provide input and approval

- Time-driven assignments with forecasted completion, so that project teams can identify schedule risk

- Automated document status changes and revisioning based on configurable workflow milestones, so progress may be tracked and integrated with project schedule

- Email notifications and mobile participation, to avoid delays from remote or offline users

Proarc automates review and approval cycles with configurable workflows. It sends notifications and assigns time-based tasks to the right stakeholders, ensuring deadlines are met and reducing reliance on email chains.

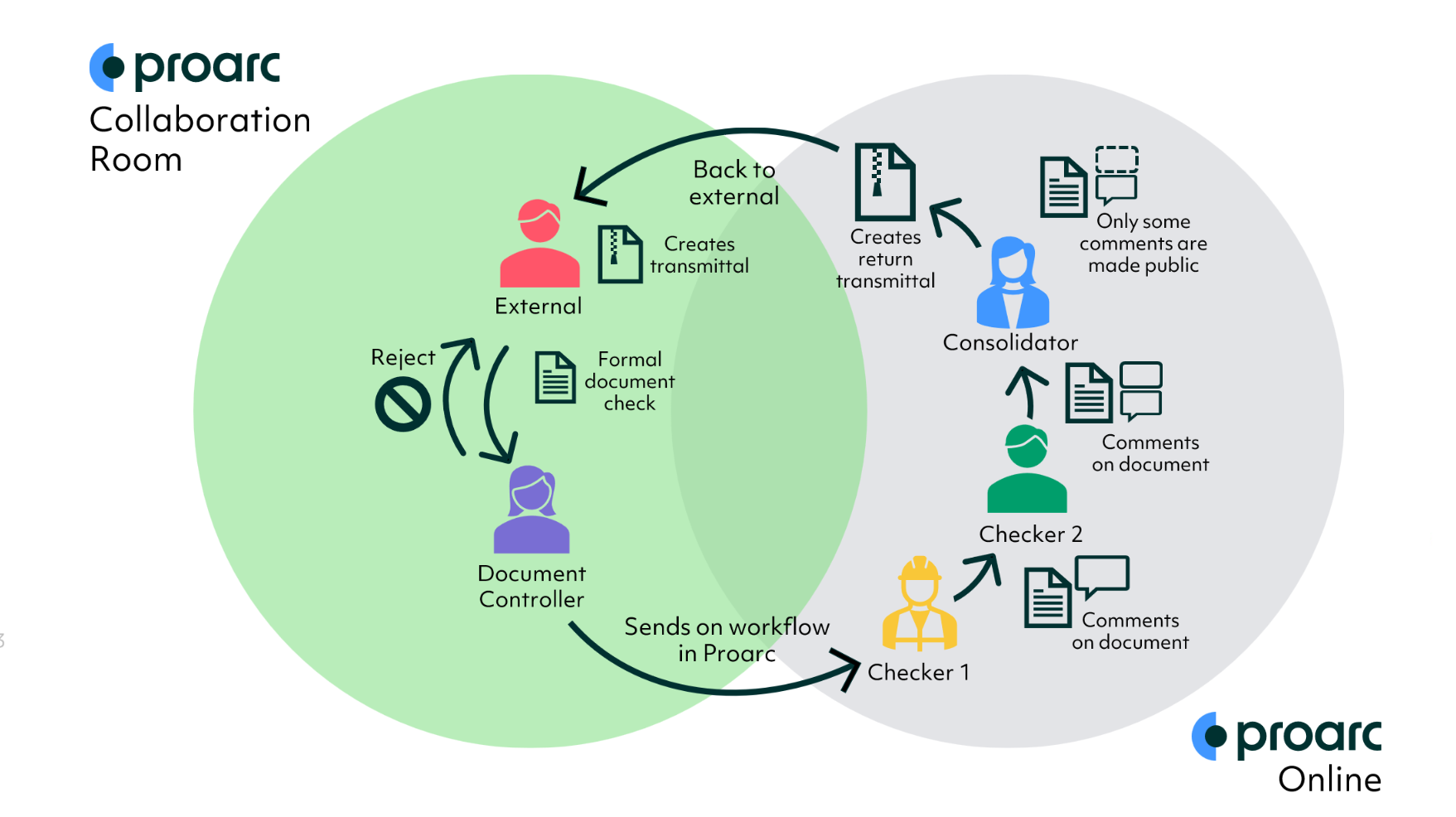

5. Cloud-Based Collaboration

Engineering projects often involve multiple teams across different locations. Secure, real-time collaboration is essential for keeping all stakeholders on the same page. Look for:

- Online collaboration environment separate from the official document management system, linked to official document revisions to avoid proliferation of uncontrolled emails and file copies

- Workflows to control how documents are shared with external participants and collaboration areas, and how changes are returned, validated and accepted to the document management system

- Integrated Microsoft 365 features, including concurrent file co-editing, to facilitate real-time collaboration

- Markup and annotation features including engineering symbols and stamping

- Unified audit history between document management system and collaboration activities

- Secure management of external participants using integrated identity management and authentication services

- REST APIs for connecting to in-house collaboration systems

Proarc offers online collaboration options that bring together internal and external users with official documents, while preserving the complete lifecycle of the official documents and ensuring information security.

Figure 1: How the Proarc Collaboration Room integrates internal and external users into the document management system.

How Does a Document Management System Workflow Improve Engineering Projects?

A workflow defines the structured path a document takes, from creation and review to approval and distribution, ensuring that nothing falls through the cracks.

A workflow defines the structured path a document takes, from creation and review to approval and distribution, ensuring that nothing falls through the cracks.

Engineering projects involve thousands of documents, each tied to critical milestones. Without automated workflows, teams often rely on manual processes like email chains and spreadsheets, which are prone to delays and errors. This can lead to missed deadlines, compliance failures and costly rework.

What Does a Document Management System Workflow Typically Look Like?

A document management system workflow is designed to ensure every document moves through a structured, traceable process. This typically involves:

1. Document Creation and Registration

New documents are uploaded and classified using metadata. This step ensures accurate categorisation and easy retrieval later.

2. Review and Approval Cycle

Documents enter a predefined sequence of reviewers and approvers. Each stage is logged, and comments are captured for full transparency. This is critical for compliance and quality assurance.

3. Version Control and Updates

As revisions occur, the system maintains a complete history of changes, preventing confusion and ensuring teams always work from the latest version.

4. Distribution and Access Control

Once approved, documents are distributed to internal teams and external partners with controlled permissions. This guarantees that only authorised users can view or edit sensitive information.

5. Notifications and Task Assignments

Automated alerts keep stakeholders informed of pending actions and deadlines, reducing delays and eliminating reliance on manual follow-ups.

6. Archiving and Audit Trails

Completed documents are archived with full audit logs, supporting compliance and future reference.

Proarc EDMS offers configurable workflows tailored for engineering projects. It automates review and approval processes, integrates advanced metadata tagging and provides real-time notifications.

Summary

A well-designed document management system ensures accuracy, traceability, and compliance while streamlining workflows and improving efficiency. Purpose-built solutions like Proarc EDMS go beyond generic tools by supporting engineering-specific needs such as managing complex multi-file engineering documents and their interdependencies, enforcing revision-level control (not just file versions), providing metadata-driven navigation like dynamic folders, and automating review cycles with configurable, discipline-specific workflows.

To learn more about how Proarc can help your team deliver engineering projects with confidence, download the Proarc EDMS brochure today.

Document Management Systems for Engineering FAQs

-

The benefits of a document management system for engineering projects include:

- Risk reduction through controlled engineering revisions (not just file versions) and complete audit histories

- Stronger collaboration using Proarc’s controlled supplier/client submittal workflows and linked collaboration spaces tied to official document revisions

- Faster document retrieval using metadata-driven forms, reusable queries, and dynamic folders based on tags, systems and work packages

- Reliable compliance through enforced document numbering standards, classification rules, access controls, and deviation detection

Proarc EDMS delivers all these benefits with features tailored for engineering environments, helping teams manage complexity and maintain control throughout the project lifecycle.

-

SharePoint can handle basic document storage, but lacks engineering-specific features such as official engineering revision control, multi-file document handling with references, discipline‑specific review workflows, dynamic folders driven by tags and systems and metadata structures aligned with engineering standards. These gaps often lead to inconsistent data, uncontrolled revisions, and extra manual effort. Proarc EDMS offers purpose-built capabilities for accuracy, traceability, and collaboration.

-

Cloud-based document management systems enable secure remote access and real-time collaboration, which are both critical when projects involve multiple teams and locations. With Proarc EDMS, cloud deployment offers enterprise-grade security, instant updates, and seamless integration with existing tools. This ensures that everyone works from the latest version of every document, no matter where they are.