Mpower and Woodside

Woodside is Australia’s largest publicly traded oil and gas exploration and

production company and one of the world’s leading producers of liquefied natural gas. In 2010, Woodside completed construction of its Pluto LNG Project – Australia’s second biggest resource project.

The Hook-Up

The final construction stage of the Pluto LNG project was the “hook-up" where the platform is physically connected to the field. A hook-up involves numerous tasks that need to be completed in a predefined manner following a clear schedule to ensure the platform is connected in a safe and timely manner.

The Challenges

Woodside used Oracle Primavera software for all planning and scheduling functions and required it to be kept up to date with activities, resourcing, and progress. In order to control the hook-up process, Primavera needed to be given: the list of tasks due to be completed, the resources required, and when the tasks were due. Armed with this information Woodside could successfully plan the project.

In addition, Woodside needed to ensure that man hours expended, estimates and actual completion data for all work was collected so they could accurately control the project. Primavera did not cater to all this data nor was it capable of processing all the information required by Woodside to enable their engineers to manage the hook-up planning process effectively.

The Requirements

- Define and quantify the hook-up work required

- Scope out and estimate all hook-up jobs and associated activities

- Create job cards and man-hour estimates

- Schedule job cards and resources

- Register and allocate labour

- Time write against identified jobs

- Track progress of job cards

- Compare estimates against actual man hours

The Solution

This is where Ascertra’s experience in project management software solutions was called upon to assist Woodside on this project. Used successfully by elements of the project management team in a similar hook-up project on Sakhalin Island, Ascertra’s Mpower system was identified as being most suitable to provide these crucial functions:

- Design and deploy interfaces with Woodside’s Primavera system to enable job cards to be scheduled and planning information to be passed back to Mpower to enable time writing

- Configure electronic timesheets to allow hours to be entered weekly for onshore staff and daily for offshore staff to be completed by designated individuals

- Enable interfaces with Woodside’s Primavera system to allow progress to be tracked and

collected - Deploy the HR system to ensure that only agreed individuals could write time to job codes

- Design and deploy systems to ensure that timesheet anomalies be identified and corrected after investigation

- Produce reports to assist management

Implementation

The implementation of Mpower resulted in a system which allowed Woodside to create engineering job cards, schedule and progress them in Primavera and pass the planned jobs back to Mpower to write time against. This enabled Woodside to have access to the accurate and relevant information about the status of the hook-up project instantly.

Mpower was implemented at project inception and the team worked closely with Woodside to ensure a smooth and accurate install. This was achieved by producing a workable plan which ensured adequate participation by all stakeholders including the project team and their IT team.

Initially, the data was set up, initialised, and interfaced in Aberdeen, Scotland. From there it was moved to Woodside’s corporate headquarters in Perth, Western Australia, where the data load, job card creation, and initial scheduling took place with Woodside personnel working in conjunction with Mpower's personnel. Finally, the system was installed on the offshore accommodation and operations barge that sailed to the hook-up location in the Carnarvon Basin. From its new location, the system went 'live' and the process of the hook-up could begin.

The Endorsement

During the life of the project hook-up, the Mpower system recorded nearly a

thousand jobs and over 30,000 estimated man-hours that had to be completed before the hook-up was finished.

Woodside reported that they finished the project on time and on budget.

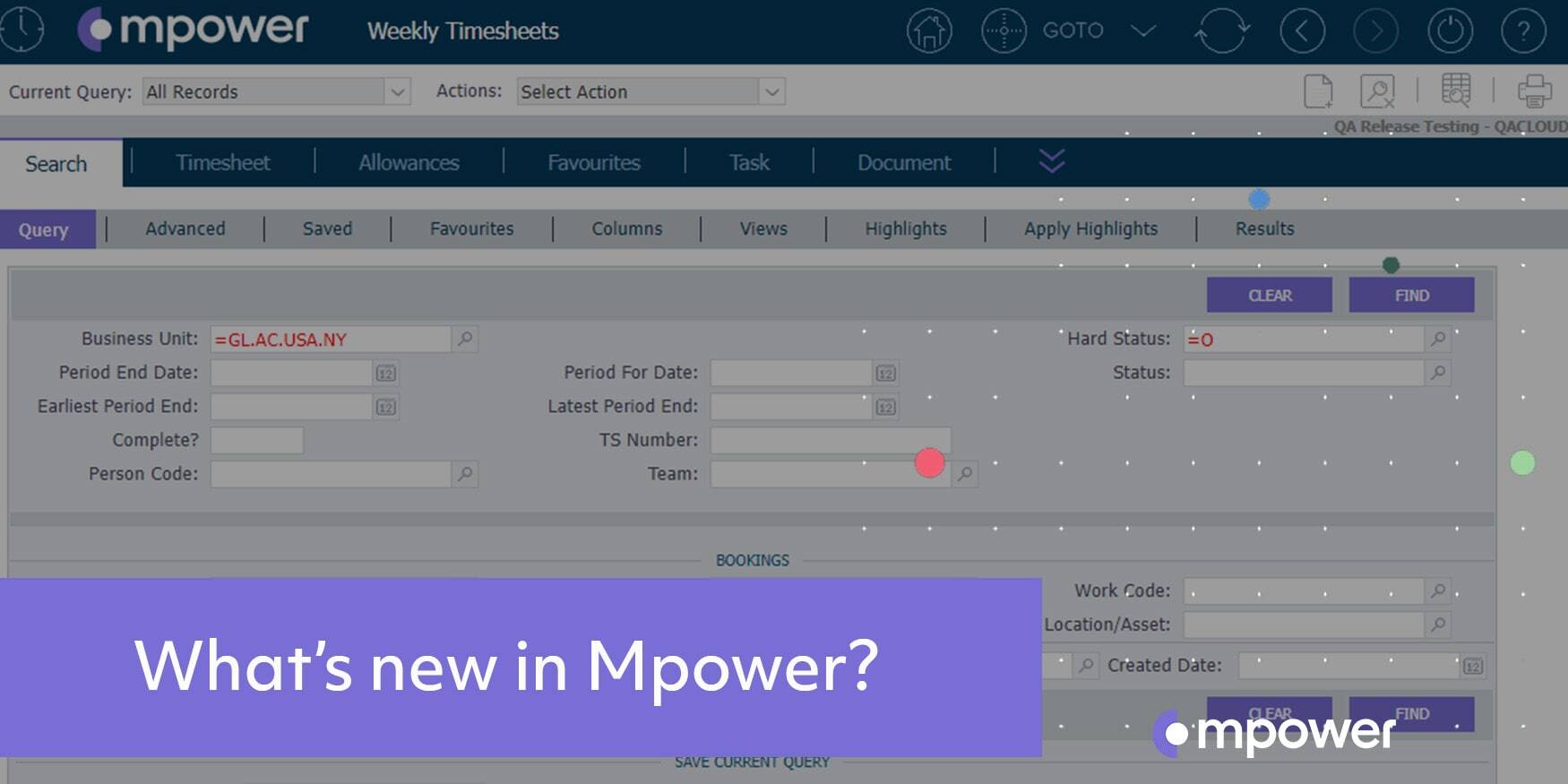

Learn More About Mpower

Mpower enterprise project control and cost management software helps project-based organizations accurately control, measure, and predict project performance. To learn more about the numerous capabilities this software provides and the value it provides to projects, visit Mpower Project Control and Cost Management software or contact us to speak with one of our solution consultants.